USAGE:

The equipment is used for blending, dispersing, homogenization and emulsification of fluid liquid material.

Food industry: edible coloring matter, chocolate coating, filling food, syrup, flavoring, various additive, etc;

Medicine industry: medical ointment, ointment, lotion, cream, various vitamin, etc

Chemical industry concerned with product of daily use: shampoo, detergent, cream, tooth paste, paraffin liquor, hair dye, etc.

Adhesive industry: rubber liquor, polyester sulfured, silicone, hot-melt adhesive, polyurethane, etc.

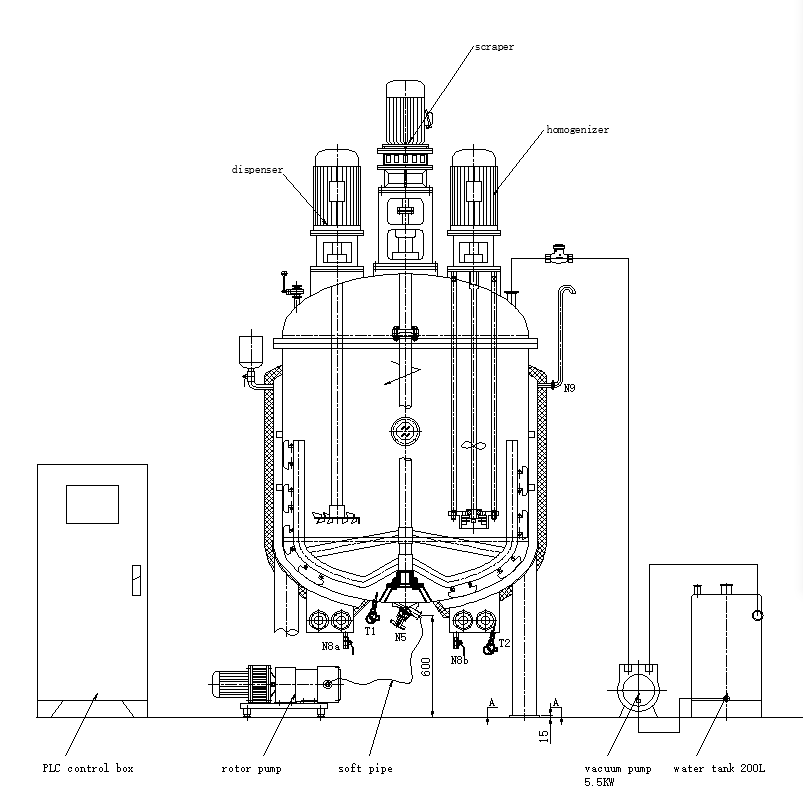

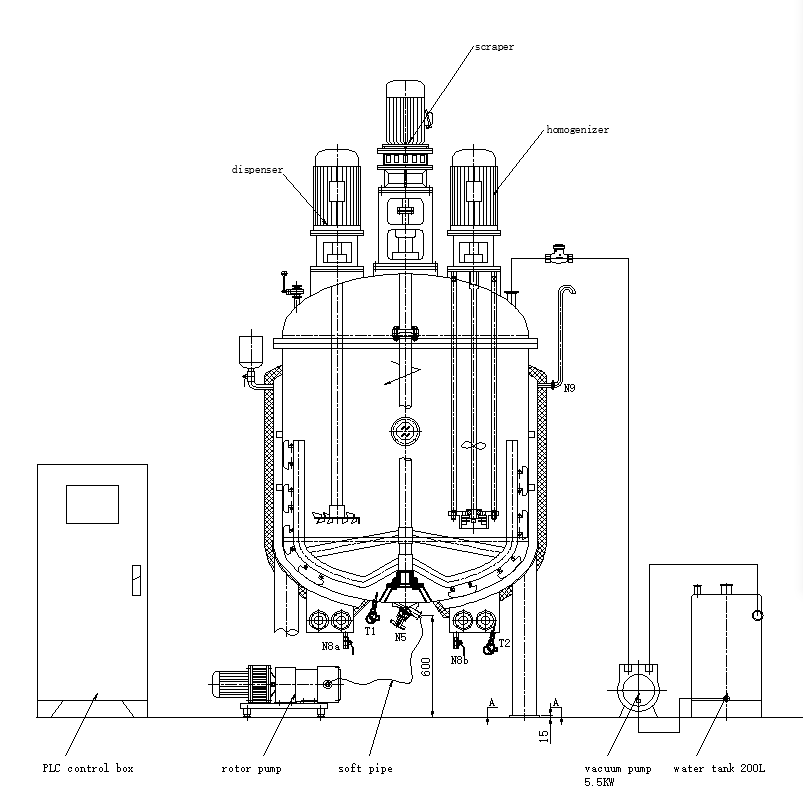

STRUCTURE:

The machine include double jacket, mixer, temperature sensor, pressure meter, control box.

This mixing tank has three layers, inner layer was the contact part with your raw material such as milk, juice, cream or any other liquid product鈥?outside the inner layer, there is a heating / cooling jacket for steam or hot water / cooling water. Then comes the outer shell. Between outer shell and the jacket, there is a 50mm thickness temperature preservation layer.

FEATURE:

1: Blending system adopts single-direction or double-direction wall scraping blending to satisfy different technological requirement

2: Frequency conversion speed adjustment.

3: Material can be heated or cooled according to technological requirements

4: Electric heating or steam heating

5: Various forms of blending vanes are suitable for production of different types of products.

6: Made of imported SUS304 or SUS316L stainless steel. The tank body and pipe are subjected to mirror polishing

7: Bottom installation type dispersing head and FLUKO pipeline type emulsifying head are optional to speed up dissolution and emulsification of materials.

8: The stainless steel electric control cabinet can completely supervise the operation of equipment, and display such data as temperature and blending rotation speed, etc

9: High-speed disperse (homogenizer) strongly mixed decentralized thick, solid, liquid.

cosmetic producing machine;cosmetic producing machine; cosmetic producing tank; daily chemical stirring vessel ; detergent agitator boiler ; detergent agitator pot

INSTALLATION:

1 put the machine on the flat floor and check it is stable or not, if not, pleas adjust the leg until to stable

2 please check it is heated by steam or electric. If it is heated by steam, you connect the steam pipe flange to steam boiler pipe and install the safety pressure valve , must take care of the steam pressure when you heating and connect the steam trap valve

If the machine is heated by electric, you connect the electric heater to control box according to the electric drawing

3 connect the motor and temperature sensor wires to control box according to the electric drawing

4 check all the meters and sensor are working well or not

5 clean the tank before working

NOTICE:

Must be care for the pressure and temperature when you are working, it must be according to the requirement of the parameter.

Install picture:

The finished product:

Prev锛?a href="/a/product/50.html">Up homogenize mixing tank

Next锛氭病鏈変簡!

WenZhou Create Machinery Co Ltd.

WenZhou Create Machinery Co Ltd.